The company has developed a full range of value added services since the introduction of its first profile machines in the 1970s.

In addition to the cutting of steel we offer a comprehensive range of finishing services enabling you to buy the part rather than the plate. Linked to our quality systems we offer additional testing to confirm exact material suitability prior to fabrication.

scroll down

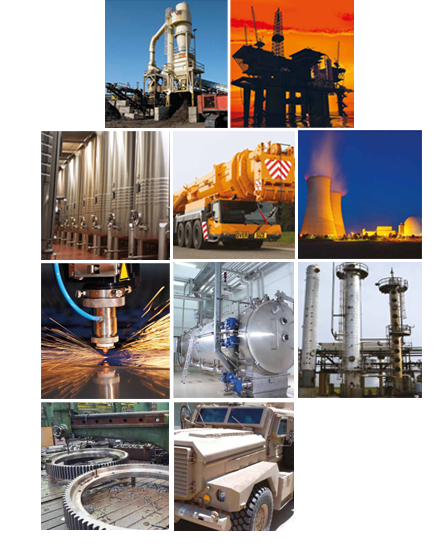

The company has developed a full range of value added services since the introduction of its first profile machines in the 1970s. In addition to the cutting of steel we offer a comprehensive range of finishing services enabling you to buy the part rather than the plate. Linked to our quality systems we offer additional testing to confirm exact material suitability prior to fabrication.

Processing reduces handling costs and provides a fast efficient service delivery cut pieces as and when required for production by utilising our extensive range of processing equipment and technologies:-

Oxy-Propane, High Definition Plasma, Laser Cutting, Water Jet Cutting

We are leading the Uk market with our recent introduction of Infinity Plasma Profiling featuring contour profiling technologies. This enhances our Capability to produce highly complex profiles that include multiple various sized holes, slots, counter sunk holes and superior bevels on radiuses, diameters and any non-standard shapes both internally and externally in a single automated operation with variable angles.

Maximum thickness - 400mm Maximum piece of weight 50 tonnes Maximum piece width 4.8m Maximum piece length 16m (24m with restrictions)

Our finishing services allow you to purchase the finished product from one source.

Machining, Drilling, Bending, Weld Preparation, Grinding, Welding, Rolling, Shot Blasting & Painting, Dished Ends

Maximum thickness -

400mm Maximum piece of weight 20 tonnes

Working with both mill and international approved test houses we are able to offer a complete service for testing and re-testing of all steels. Most of our steel plate is purchased well in excess of various international standards, allowing us to re-test to higher specifications where possible. Our services include:

Re-certification, HIC to all NACE specifications, Sulphur Stress Cracking (SSC), Ultrasonic's to the highest levels, Through Thickness Tensile (TTT), MPI/DPI, Check Analysis (PMI), Hardness, Bend Test, Room Temperature and Elevated Temperature Tests, Simulated Post Weld Heat Treatment, Lloyds, DNV, ABS, Royal Sun Alliance and all third party witnessed tests.

Our project management team led by graduate project manager(s) are regularly involved in projects in the U.K. and worldwide in the nuclear industry, and boast industry leading involvement in wind tower production, and tank farm pre-fabrication and installation planning.

The Brown McFarlane approach provides a single point of contact to our customers guaranteeing them a “hands on” management strategy throughout all stages of their project right from the initial formulation of a project plan through to the final hand over of the completed project documentation pack. We pride ourselves on taking all of the stress out of material and component sourcing, preparation and delivery to site for assembly.

With more than 100 years experience of moving steel and equipment around the U.K. and across the world we are able to offer our customers assistance and support in getting their steel to the right place at the right time.

We have delivered small cut pieces weighing a few kilograms by courier, steel plates weighing several tonnes by air, and two thousand tonne shipments to the other side of the world. In short, whether it be by road, sea, or air, whether it is a domestic or international shipment, or whether it is small or large, we have almost certainly done something similar already and can help you by doing it again.

Our main stock holding facility is in the UK midlands holding a full range of High Specification Carbon, HIC , stainless, Duplex and Super Duplex steels and holds significant stocks of High Specification Carbon and HIC steels in Antwerp (our main shipping hub) ; we also have access to large stocks of steel plates in other strategic locations around the world enabling us to supply a full range of quality assured steels at very short notice to any part of the world.

Intelligent market monitoring ensures that sufficient stocks of particular High specification steels are available at all times.